cad/cam

design

construction

dies

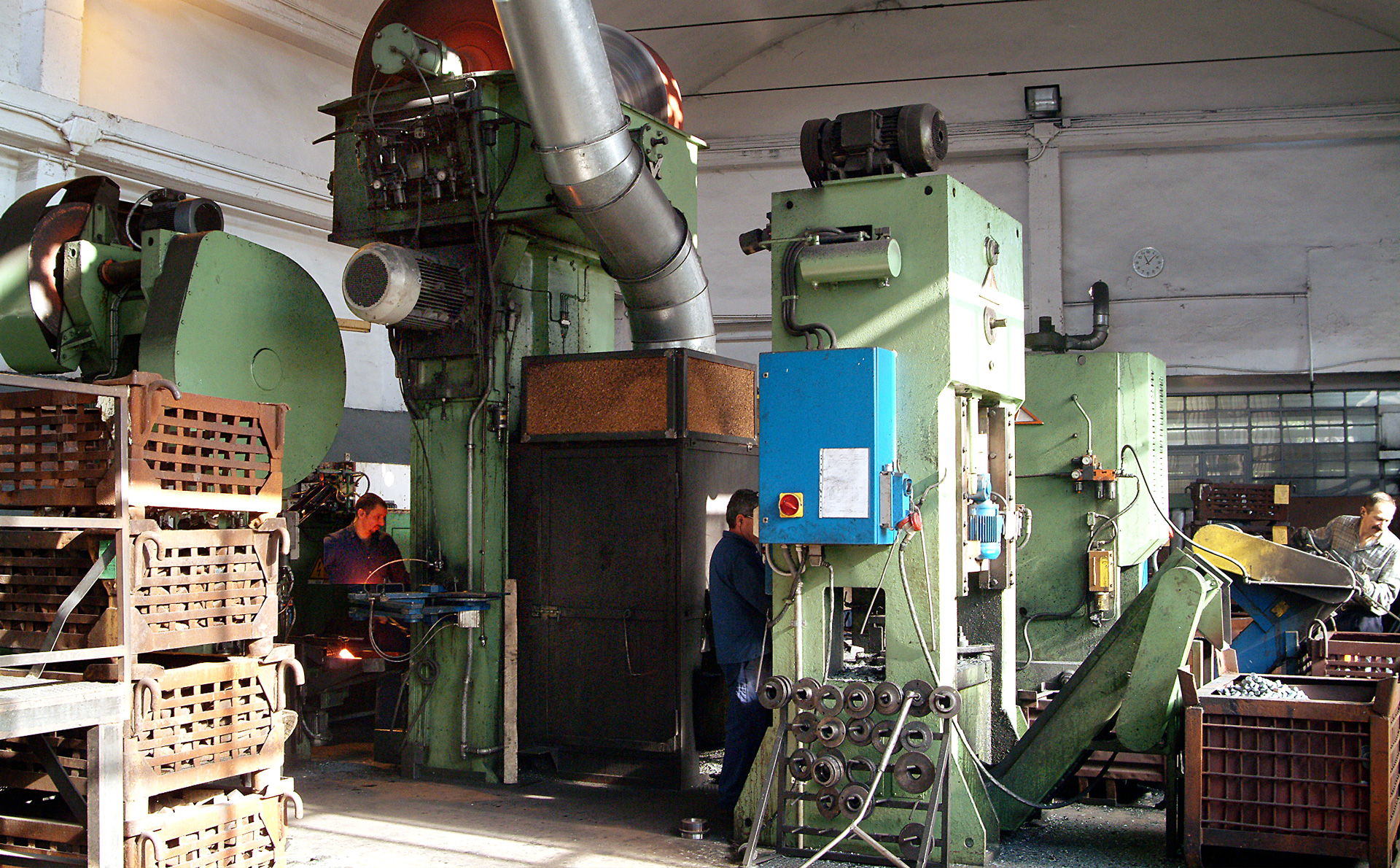

shearing

department

heating

and printing

Engineering and Design Department

BERSANO CARLO has the expertise and resources supervise the life of a product from the design phases

to the production according to customer requirements.

In order to optimize the development of molds and equipments we use FEM simulation hot forging software.

The development of production tooling designs and machining schedules for machine tools are handled by the Engineering Department aided by the latest up to-date CAD/CAM systems.

Video of Molding simulation to CAD

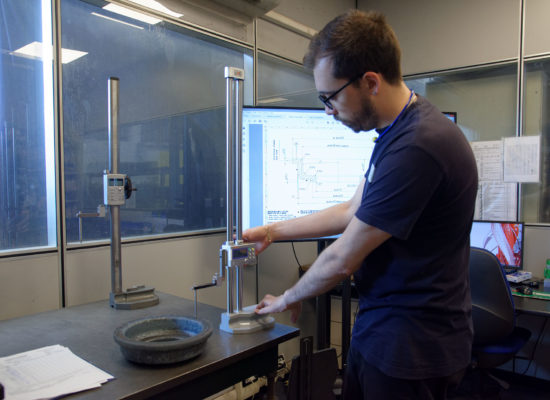

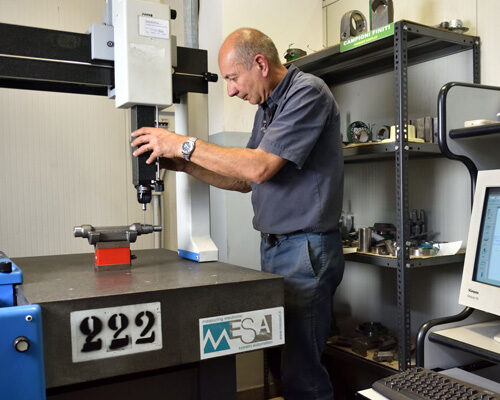

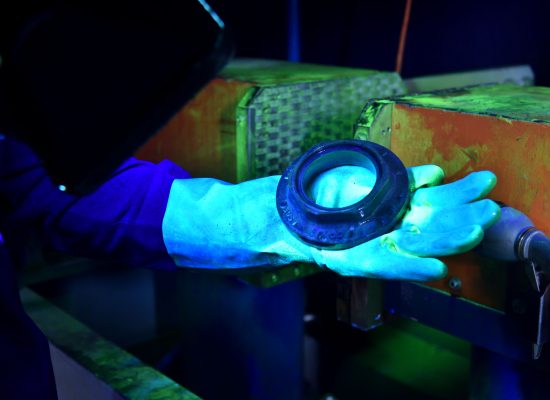

Testing

A final check is carried out on each particular product to ensure that corresponds to the customer’s requests.